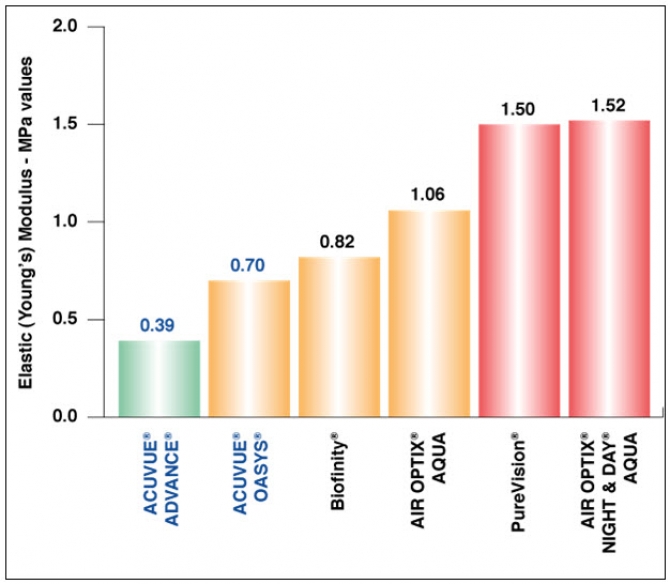

Modulus

The property of modulus or "stiffness" is not something we used to think about with hydrogel lenses. It is relevant for silicone hydrogels as the addition of silicone often results in a lower amount of water in the lens; the combination and balance of these factors leading to silicone hydrogel lenses generally having a higher modulus than hydrogel materials.

Modulus is a measure of how a material will deform and strain when put under pressure. Elastic or Young's modulus (E) is described as the ability of a lens material to align to the ocular surface and resist deformation under tension.

E=stress/strain

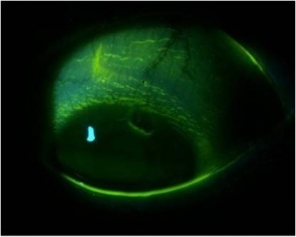

Modulus is of course relevant clinically. A lens with too low a modulus would be more difficult to handle for the wearer and give insufficient movement on blink leading to poor tear exchange. However, too high a modulus can lead to mechanically induced pathology such as SEALs and CLIPC.

Mechanically induced complications from high modulus silicone hydrogels:

superior epithelial arcuate lesion (SEAL) and contact lens induced papillary conjunctivitis (CLIPC).

Read on here to see how this property influences comfort.

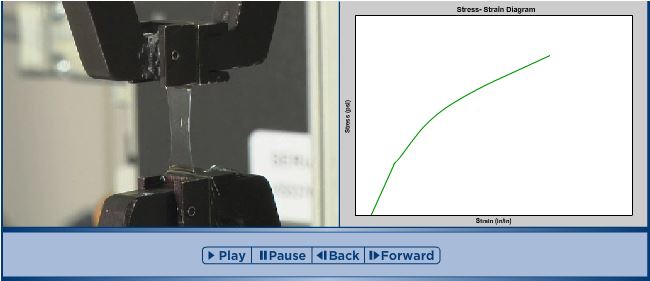

Dr Lenora Copper explaining the methodology used to measure modulus

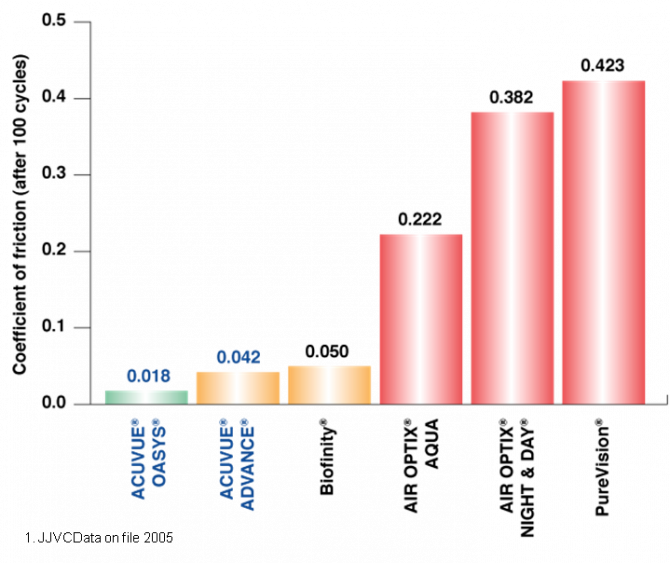

Coefficient of friction

The coefficient of friction (CoF) refers to how lubricious the surface of the contact lens is. It is sometimes referred to as lubricity and a lower CoF helps to give lenses a silky, smooth feel. It is quantitatively measured via microtribometry. The set-up is designed to mimic in vivo (on eye) eyelid interactions.

The video shows the process of obtaining the measurement. The contact lens is mounted on a firm base. The lens and measurement tip are immersed in a solution that models the composition of tears, and mucin is applied to the tip. A precisely known force is applied to the contact lens and the tip is then moved from side to side. This is repeated with a higher force where more resistance will be found. For comparable results an independent laboratory measures lenses in the same way at the same time from all manufacturers. The results are shown in the graph.

Coefficient of friction is an important property of a contact lens that closely correlates to lens comfort.

Read here to see how this property influences comfort

Schematic representation of the measurement of coefficient of friction.

Dr Lenora Copper speaking about how the technique is performed

Wettability

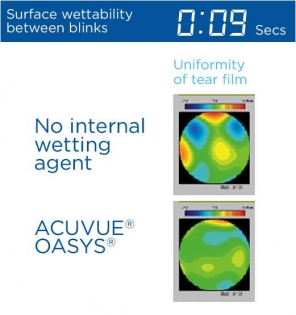

The degree of wetting is determined by a balance between adhesive and cohesive forces acting on a lens surface. Contact lenses that can sustain complete wetting allow a thick coverage of the tear film, a smooth recovery of the tear layer after eye closure and good visual acuity.

Wettability is determined by measuring the contact angle; the smaller the contact angle the greater the wettability.1 Contact angles can be classified as dynamic or static, advancing or receding.2 There are a number of methods that can be used to determine the contact angle: Wilhelmy plate, captive bubble and sessile drop.

Whatever method is used, comparisons between materials can only be made if the same methodology is used throughout. Even then, there are significant questions on the link between in-vitro and in-vivo wettability. This has led some researchers to use other techniques to look at wettability. Koh et al examined the visual performance in terms of optical quality and tear layer stability to understand the impact of wettability on the wearer. They found that the tear layer and vision was more stable in between the blink when a lens containing an inbuilt wetting agent was worn compared to a lens that did not have this.3

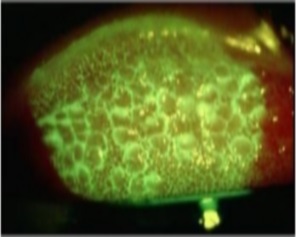

Aberrometry images showing more stable visual results attributed to enhanced wettability with internal wetting agent3

Dr Lenora Copper speaking about how wettability can be measured.

1. Menzies KL & Jones L. Optom Vis Sci. 2010;87:387-399.

2. Tonge S et al. Current Eye Research. 2001;23:51-59.

3. S Koh et al. Senofilcon A lens provided optical quality with fewer fluctuations and better stability than etaficon A lens in symptomatic SCL wearers. A novel method for assessing impact of surface wetting and optical quality of contact lenses. BCLA Poster 2010.